Describe the Process Used to Electroplate a Material

Once the copper plating is completed tin will be plated onto the copper to protect the circuitry while the photoresist is removed and the non-circuitry copper is etched away. If you attempt to start the chrome plating process before removing all the old material you will have several bumps and blemishes and you will ruin the metal.

Electroplating Explained Cdr Samfa Home Page

While the material thats going to cover the other metal will have a positive charge.

. Plating has been done for hundreds of years. Describes a typical modern bath for copper plating. Electroplating is the process of applying a metallic coating to an article by passing an electric current through an electrolyte in contact with the article thereby forming a.

Electroplating is mainly done for avoiding corrosion of metals and for decorative purposes. Copper electroplating process by Yutaka Okinaka ATT Bell Laboratories. The electroplating is an art of depositing a superior or more noble metal on a base metal by means of electrolysis.

It is also critical for modern technology. Plating is used to decorate objects for corrosion inhibition to improve solderability to harden to improve wearability to reduce friction to improve paint adhesion to alter conductivity to improve IR. Electroplating is a process that uses electric current to reduce dissolved metal ions by the use of electrolysis to obtain the dissolved metal ions at the other electrode mostly in the form of a uniform coating.

As the name suggests the process involves the depositing material using an electric current. The process works using four primary components. Submerge the wafer to be plated into an electrolyte bath apply a current and copper ions will migrate and deposit onto regions with a pre-existing metal seed layer.

Thus electroplating is defined as the process of plating a layer of any metal on other material by passing an electric current. The electroplating process includes dipping the board alternatively into the plating and cleaning baths under controlled conditions to ensure that the copper is evenly applied. The concept of copper electroplating is straightforward.

A generator is used to produce a vibrating action that causes the parts to move and make contact with the metal buttons. For example metals like iron are coated with deposits of nickel or chromium by electroplating to protect it from corrosion. Each material has certain benefits that make it applicable to specific applications.

This process results in a thin layer of metal being deposited onto the surface of a w View the full answer. The plating process is a manufacturing process in which a thin layer of metal coats a substrate. Electroplating is a process that uses an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode.

Electro nickel plating is a process that uses an electrical current to coat a conductive material typically made of metal with a thin layer of nickel. The metal to be plated will be given a negative charge. A detailed description of the kind of electroplating processes used in making integrated circuits.

Electroplating is done by the process of electrodeposition and involves the formation of an electrolytic cell consisting of the cathode. Repair and Restore Fill any cracks crevasse or holes with brass or lead. Many elemental metals and some selected alloys can be used as plating materials.

The part to be coated acts as the cathode of an electrolytic cell. The materials will be attracted to each other once a current is then passed through. Electroplating is also known as electrodeposition.

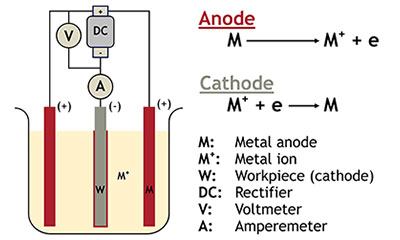

Image of electrolytic plating cell. Electroplating is the process of coating one metal over another by using electricity mainly done to provide protection from corrosion. Plating is a surface covering in which a metal is deposited on a conductive surface.

Using the electroplating process enables to change the chemical and physical properties of a metal. For example gold is an excellent conductor and resists corrosion so it is often used for electrical contacts and. And the anode is usually either a block of that metal or of some inert conductive.

Adult supervision and chemical safety equipment required Watch us use electricity to copper-plate a brass key copper electroplating in this Home Science Tools video. Outline key health and safety considerations of each process. Metal plating provides many benefits to products made from metal and other materials.

Electroplating is a general name for processes that produce a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. Describe the procedures for the hot process anodising and plating methods outlined below when used for finishing on different given components. Dont skip hard chrome plating process steps to save time or money.

The Electro Nickel Plating Process. Electro nickel plating also known as nickel electroplating or nickel electro-deposition is becoming an increasingly popular process for a variety of different manufacturing applications. Plating Materials Elemental Metals And Some Selected Alloys.

The electrolyte is a solution of a salt of the metal to be coated. In the word Electroplating electro refers to electric current and plating refers to an act of outer covering of some materials with a thin layer of a different metal. Vibratory plating is typically the most expensive form of tin plating and.

Also used for delicate parts vibratory plating involves placing the parts in a basket equipped with metal buttons that also contains the electrolytic plating solution. What effect will these processes have on the finished component surface finish and hardness. In copper electroplating a metal substrate is placed in an electrolytic bath and an electric current is used to cause copper ions to adhere to the base materials surface.

The electrolyte bath contains three primary inorganic components. For hot process the component is made from steel. This is mostly achieved through electroplating which requires an electric current or through electroless plating which is in autocatalytic chemical process.

The electroplating process uses an electric current to dissolve metal and deposit it onto a surface. Clean surface Strip for replating Roughen surface Water rinse Electroplate layer 1 Water rinse Electroplate layer 2 Water rinse Strike or Zincate Post-plating coating Buffing grinding or machining Pre-bake Mechanical surface. The anode or positively charged electrode in the circuit is the metal that will form the plating.

What Is Electroplating Definition Working Principle Its Uses

The Electroplating Process Broken Down Into 8 Steps

Electroplating Process How Does It Work Its Process And Applications

No comments for "Describe the Process Used to Electroplate a Material"

Post a Comment